|

1,ParMax Intro Letter;

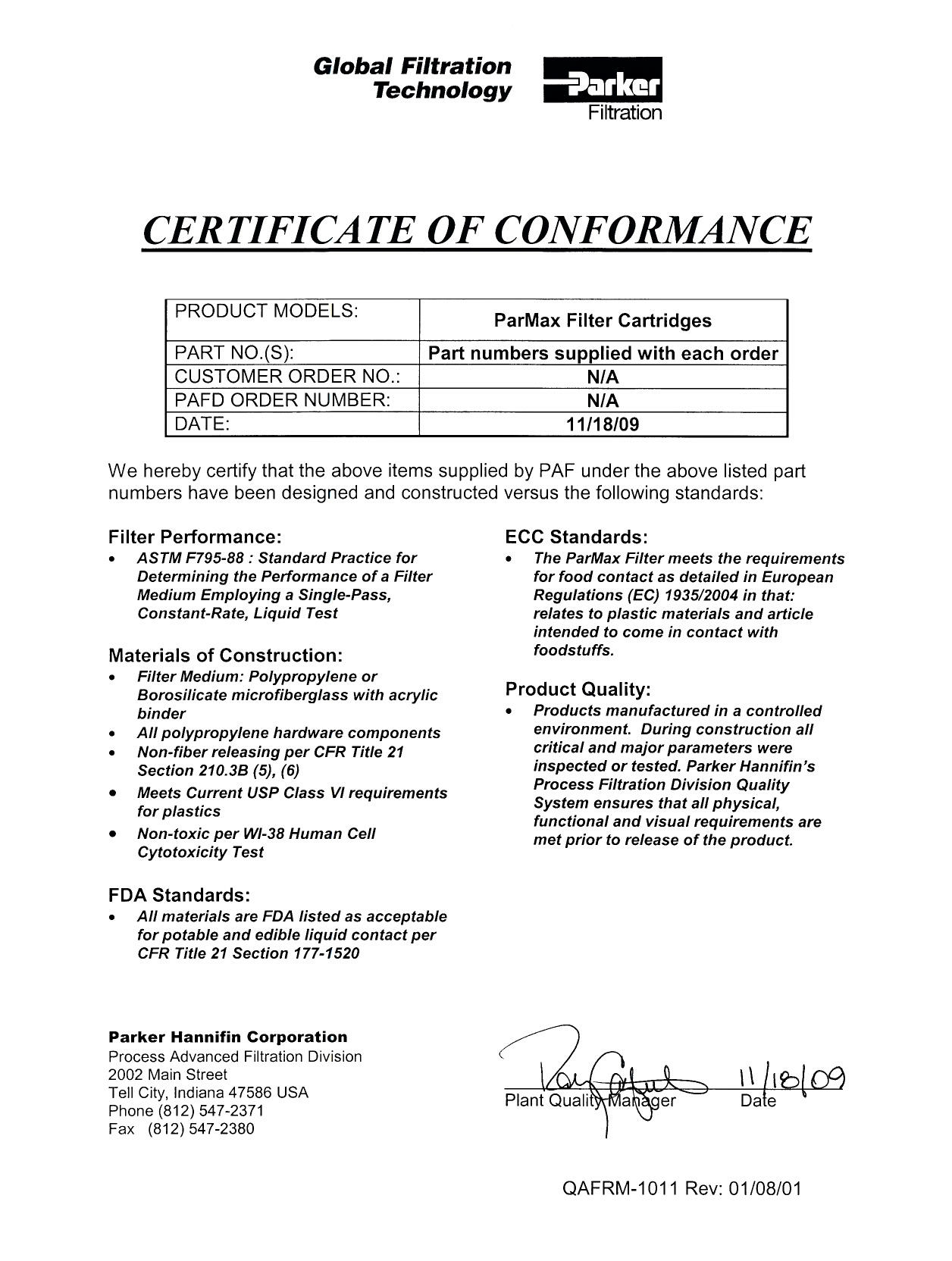

2,COC;

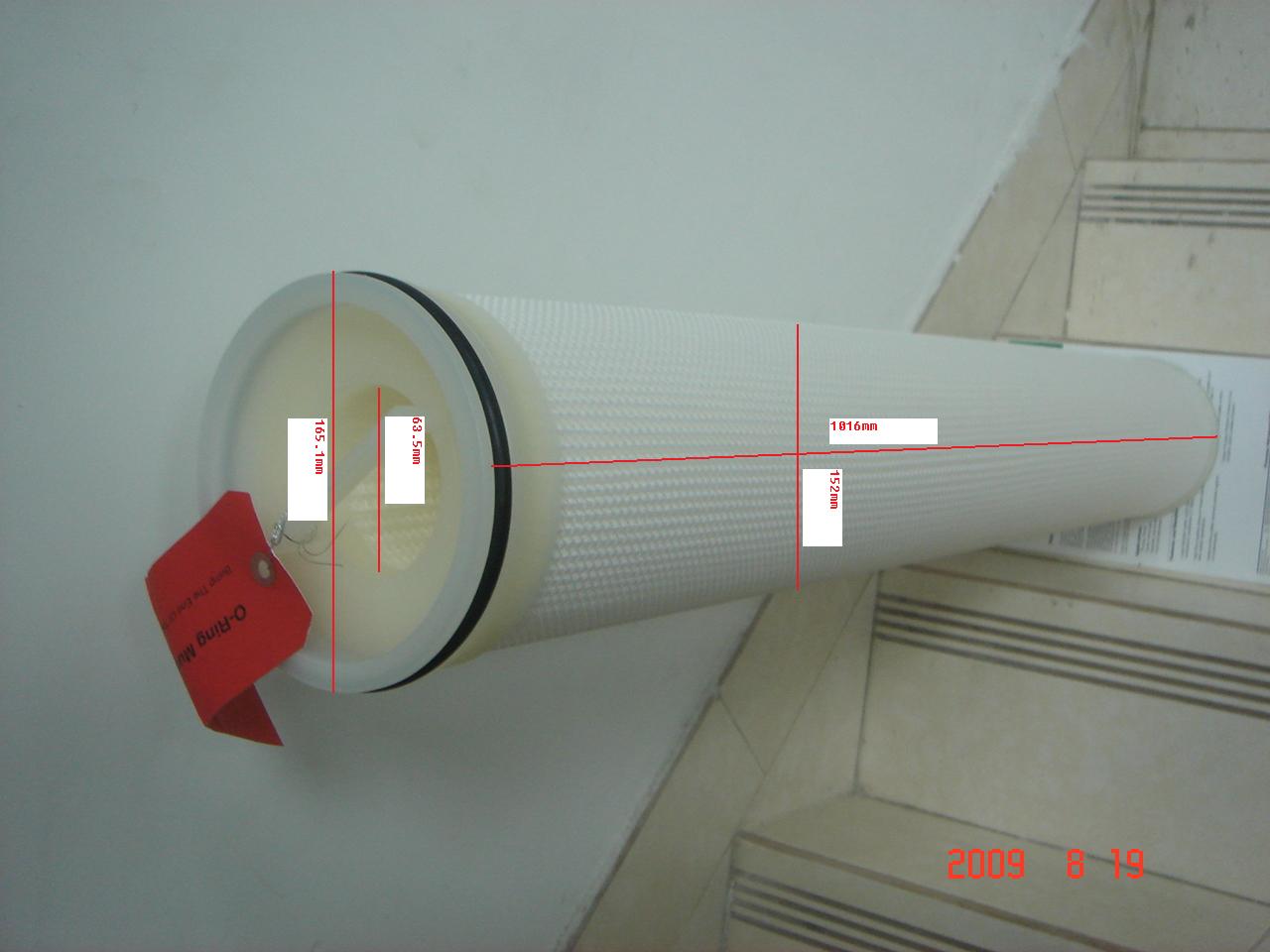

3,Out Diamensions;

To our valued Distributors & Customers:

Parker PAF is pleased to introduce the ParMax™ Select cartridge.

The ParMax Select is specifically designed to compete with the Pall HFU Ultipleat Style cartridges and similar large-diameter products with an inside to out flow path.

Why did Parker PAF develop the Select Pleat process?

To increase filter Surface Area

To Maximize Flow Rates

To Maximize Product Life

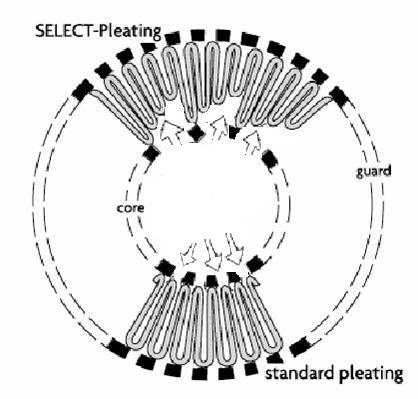

ParMax Select incorporates the Select Pleat process, a multi-staged pleat designed to add 25% more surface area in the pleat pack. As seen below, the staged-pleat design permits higher flow through the core, compared to the standard pleat design. Because of the inside-to-out flow path, there is a greater area available for collection of contaminant, allowing for a higher contaminant load.

ParMax Select is also manufactured using a Thermal Welding process. This eliminates the need for adhesives used to bond the pleat pack to the end cap. PAF’s new Thermal Welding process provides a highly reliable side- and end-cap-seal that enables use of the ParMax Select in a broader range of chemical and higher-temperature applications.

ParMax Select will enable you to sell the product to more applications in the oil & gas, chemical, water, and beverage markets. Its enhanced design provides higher flow with retention, longer service life, lower cost-in-use, and an overall higher level of filtration performance.

We consider the new product to be a significant advance over the standard ParMax. You can sell ParMax Select with confidence to your customers in a range of industries for chemical, oil & gas, pre-RO as well as food & beverage applications.

Please call me with any questions. We will be scheduling an online Training session on the new product in the very near future.

Vincent Geraci

Market Development Manager

Parker Process Advanced Filtration

Office: 317-275-8424

Mobile: 317-373-9309